Basic Info

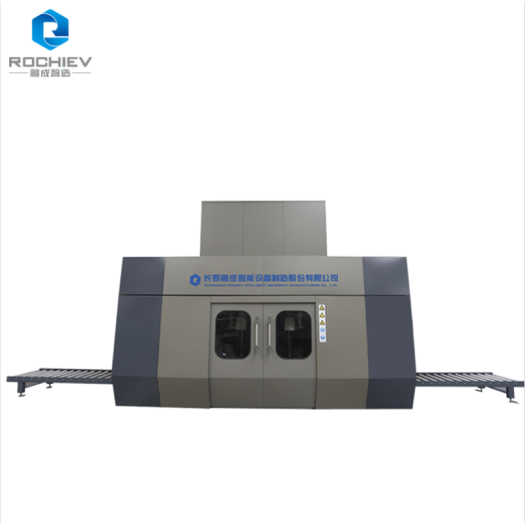

Model No.: RF61

Types of: Filling Machine

Applicable industry: Manufacturing Plant, Food &Amp; Beverage Shops, Food &Amp; Beverage Factory, Energy &Amp; Mining, Other

Out-of-warranty service: Online Support, Video Technical Support

Where to provide local services (in which countries are there overseas service outlets): None

Showroom location (in which countries are there sample rooms overseas): None

status: New

application: Beverage, Medical, Chemical, Pharmaceutical, Machinery &Amp; Hardware

type of packaging: Cartons, Cans, Bottles, Barrel, Capsule

Packaging Materials: Plastic, Paper, Glass

degree of automation: Automatic, Other

Power type: Electric, Other

place of origin: China

Core selling point: Competitive Price, Long Service Life, High Safety Level, High Productivity, High-Accuracy, Automatic

Filling material: Other, Oil, Powder

Marketing type: New Product 2019, New Product 2020

Mechanical test report: Provided

Video factory inspection: Provided

Core component warranty period: Other

Core components: Motor, Pressure Vessel, Pump

.png) Contact Now

Contact Now